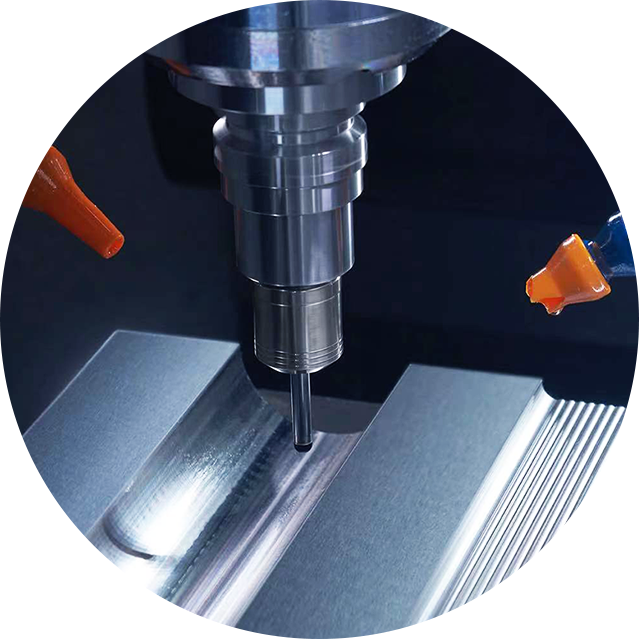

In today’s rapidly evolving technological landscape, the ultrasonic machining system has emerged as a game-changer in the manufacturing industry. This cutting-edge technology utilizes high-frequency vibrations to achieve precise and efficient material removal, revolutionizing traditional machining processes.

The Advantages of Ultrasonic Machining System

The ultrasonic machining system offers several key advantages over conventional methods. Firstly, it enables manufacturers to work with a wide range of materials, including hard and brittle substances like ceramics and glass, which were previously challenging to machine accurately. Secondly, this innovative system ensures minimal heat generation during the process, reducing the risk of thermal damage or distortion on delicate components. Additionally, its non-contact nature eliminates tool wear issues commonly associated with traditional techniques.

Introducing Conprofe Ultrasonic: Pioneers in Precision Engineering

Conprofe Ultrasonic stands at the forefront of ultrasonic machining technology. With their extensive expertise and commitment to innovation, they have developed state-of-the-art systems that deliver unparalleled precision and efficiency. Their machines incorporate advanced control algorithms and intelligent monitoring systems to optimize performance while ensuring utmost reliability.

Furthermore, Conprofe Ultrasonic offers comprehensive technical support throughout the entire manufacturing process. Their team of highly skilled engineers provides tailored solutions for various industries such as aerospace, automotive, electronics, and medical devices – enabling businesses worldwide to enhance productivity and maintain a competitive edge.

CNC Manufacturing Company: Empowering Efficiency through Automation

In conjunction with ultrasonic machining systems’ capabilities lies CNC (Computer Numerical Control) manufacturing companies that leverage automation technologies for enhanced efficiency. These companies utilize computer-controlled machinery capable of executing complex tasks with exceptional accuracy within shorter timeframes compared to manual operations.

CNC manufacturing companies integrate ultrasonic machining systems seamlessly into their production lines, harnessing the power of automation to streamline processes and reduce human error. This integration allows for increased productivity, improved product quality, and reduced lead times – ultimately resulting in cost savings and customer satisfaction.

Conclusion

The advent of ultrasonic machining systems has revolutionized the manufacturing industry by offering unparalleled precision, versatility, and efficiency. Companies like Conprofe Ultrasonic have played a pivotal role in driving this technological advancement forward through their cutting-edge solutions and unwavering commitment to innovation. When combined with CNC manufacturing companies’ expertise in automation, these technologies empower businesses worldwide to stay ahead of the competition while delivering exceptional products that meet the demands of today’s fast-paced market.

Click cnc manufacturing company.